Siemens PLC & inverter control system enable high-speed and stable operation of pulley type wire drawing machines, making them suitable for both high and low carbon steel wire. The low carbon steel wire produced can be used in various applications, including mesh nets, steel fibers, nails, staples, construction, agriculture, and furniture. Meanwhile, other steel wire products, such as prestressing wire, PC wire, springs, steel rope wire, steel cord, and bead wire for tires, can also be produced using this machine.

Overview

Product Description

The coil nail making machine is an automatic welding equipment which can be used in the nail processing.This machine welds nails at a 15° to 16° angle by utilizing two copper coated wires. Following welding, the nails are coiled to a specified length and then cut to form a coil with a flat or cone-shaped top. This machine has the capability to handle a diverse range of raw materials, such as normal wire, new metal wire, waste rebar, scrap steel bar, hard-drawn wire, waste electrodes, and other types of steel waste.

Production Capacity:2000pcs/min Warranty of core components:1 Year

Power (kW):10 Weight (KG):1600 KG

Nail Length:25-120MM Diameter of Nail:2.1-4.1mm

Process of nail making: Wire-Rod → Wires-Drawing → Nail-Making → Polishing →Rolling→Coiling→ Packing → Delivery

|

Coil Nail Collating Machine

|

|

|

Range of Nail Dia

|

1.6mm-4.1mm |

| Range of Nail Length | 25mm-130mm |

| Speed | 2500 pcs/min. |

| Rated Power | 8kw |

| Power of Nail Feeding System | 0.75kw |

| Power of Welding System | 20kw, 1000-2000A |

| Power Supply | 3 phases AC 380V 50-60HZ |

| Packing | packed in 2 wooden cases |

|

Packing Size

|

3000X1500X1800mm |

| Weight | 1600kg |

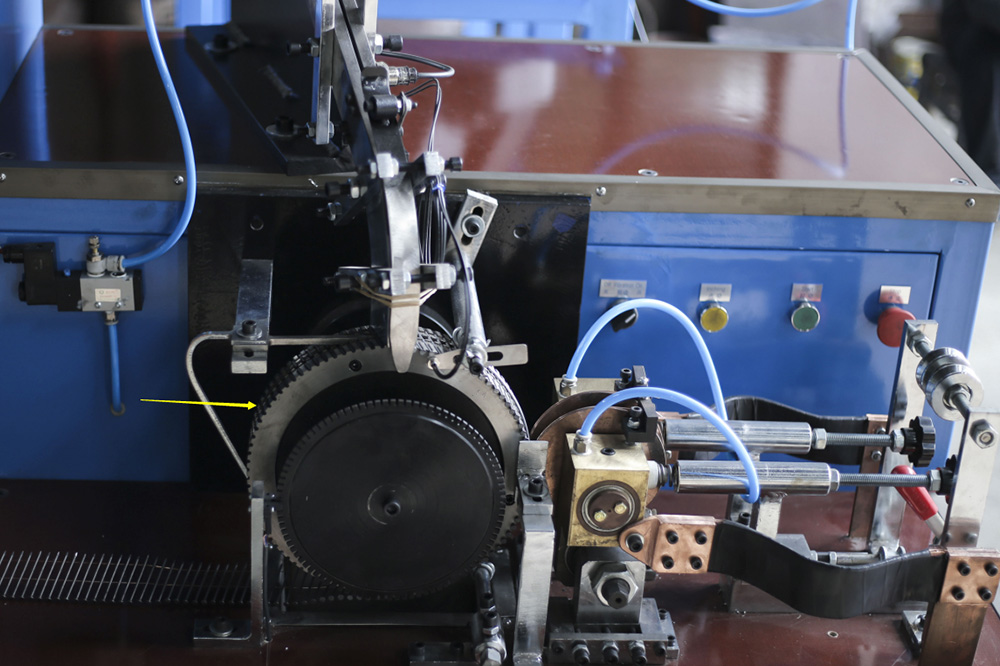

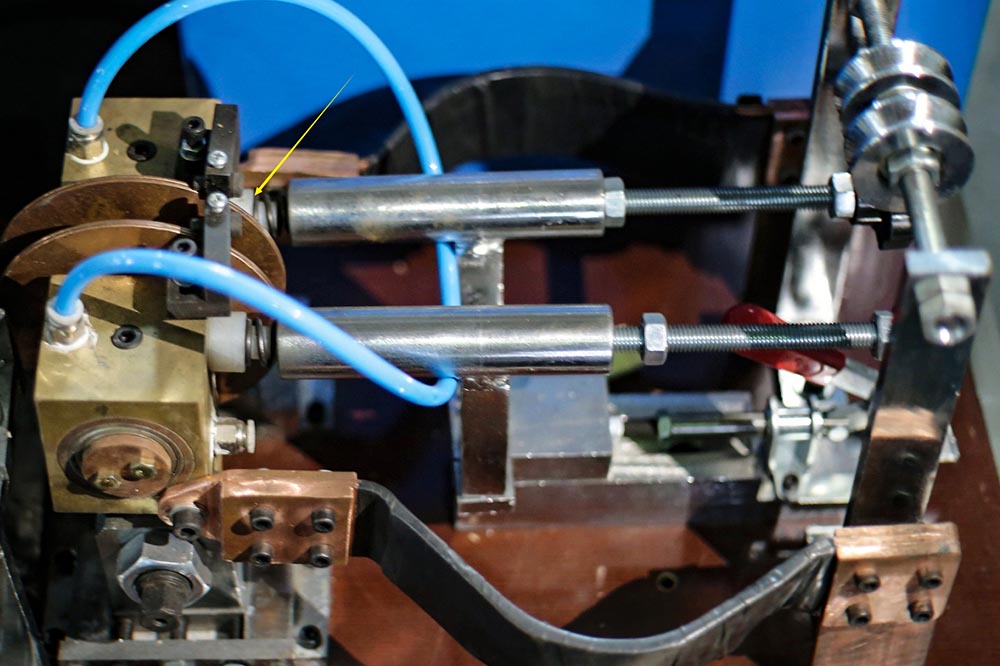

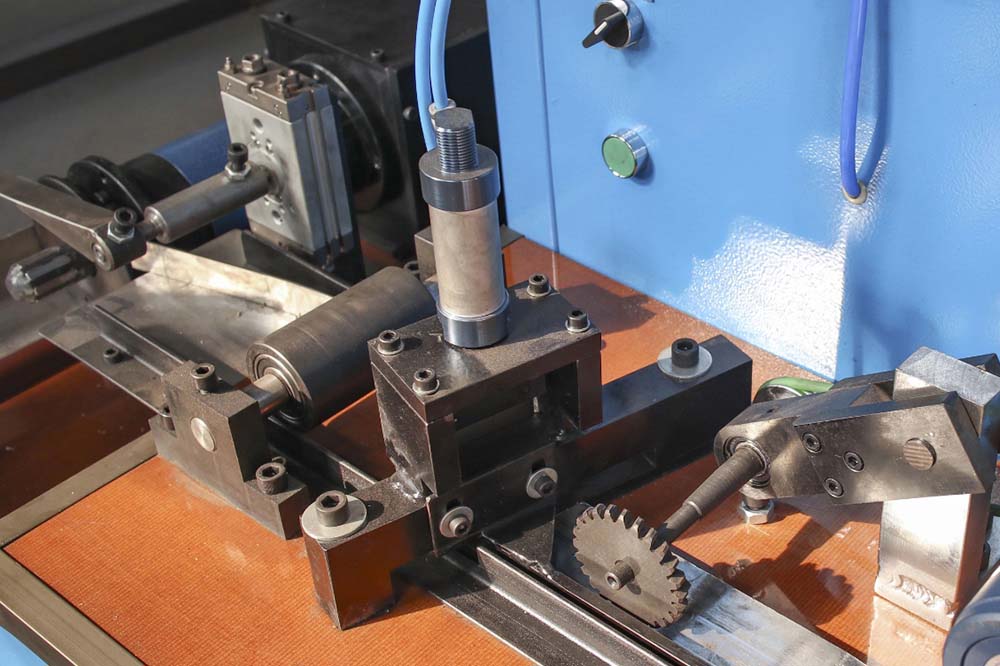

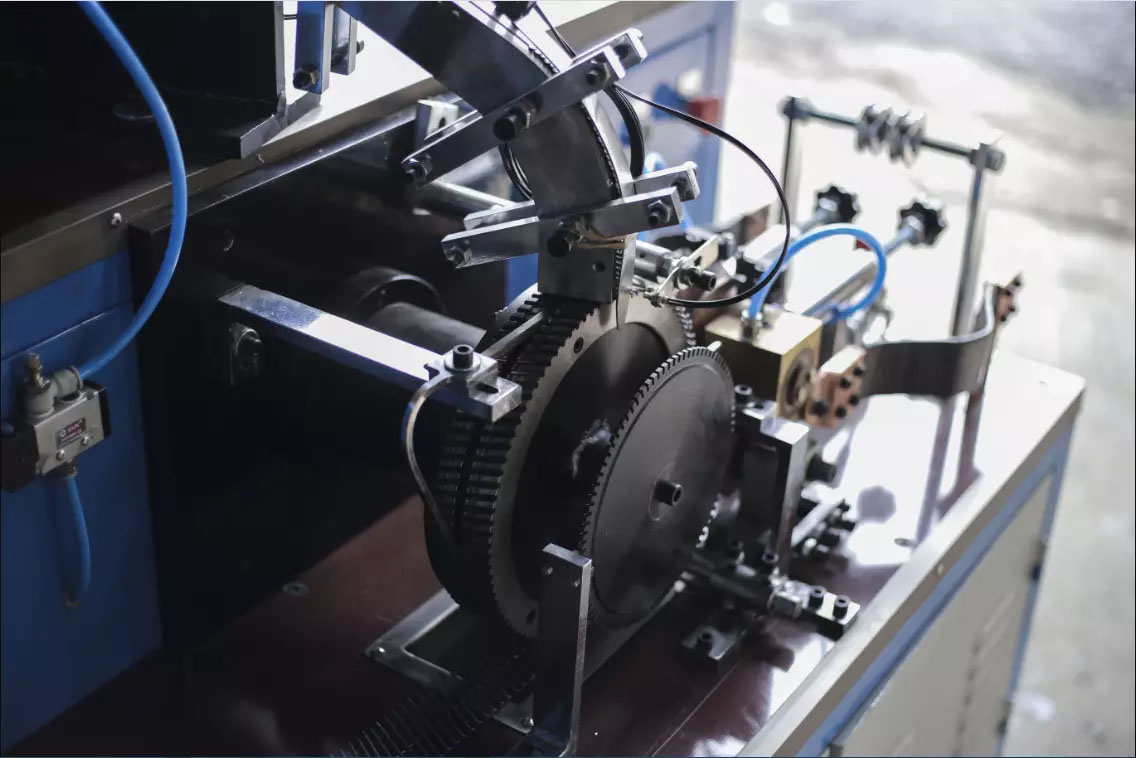

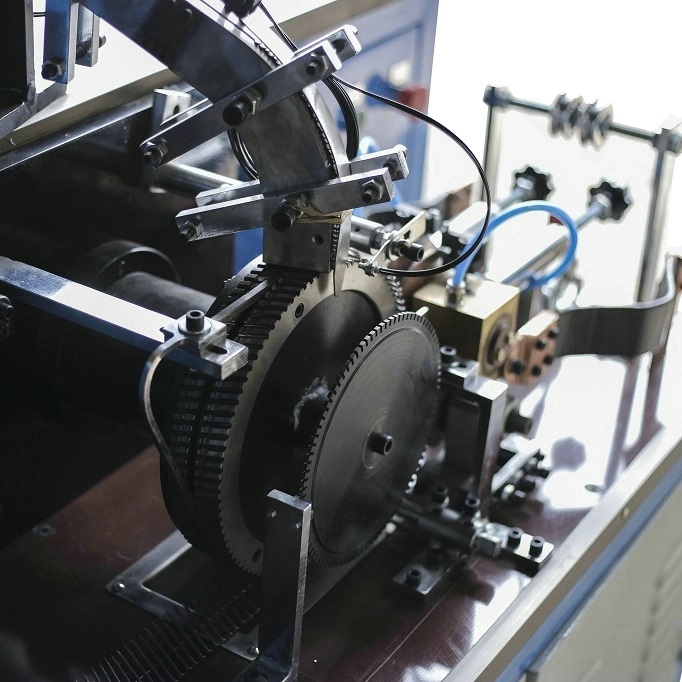

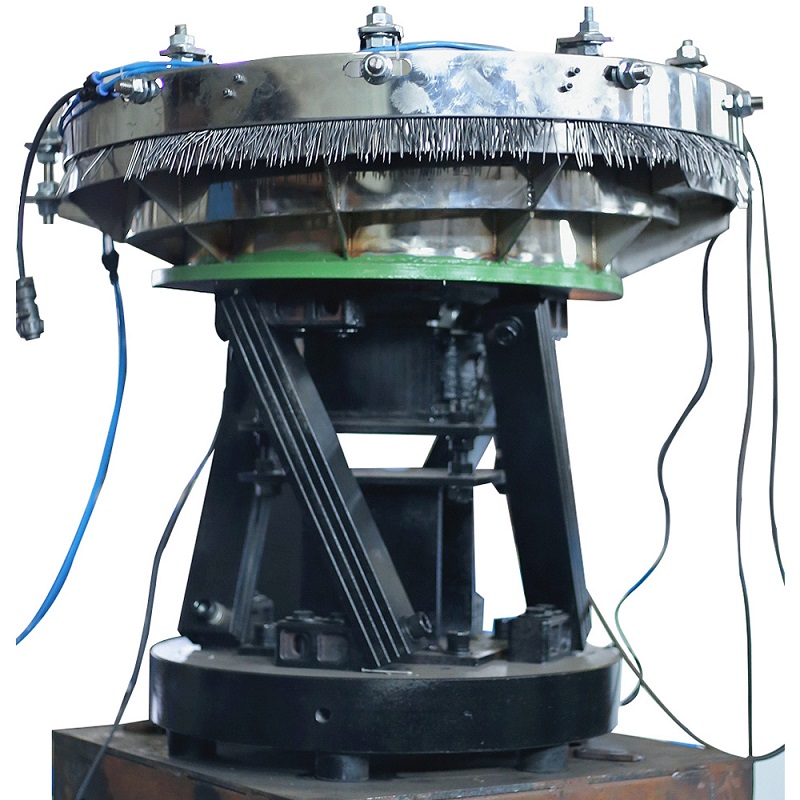

Detail images

Main Features:

1) 10years production experience with good reputation;

2) We specialize in design machines according to customers' requirements. 100 sets of machine can be supplied per month;

3) You are welcomed to visit our factory, the machines can be operated on site, and you will master the usage of machines nearby. and we also provided best after-sales service.

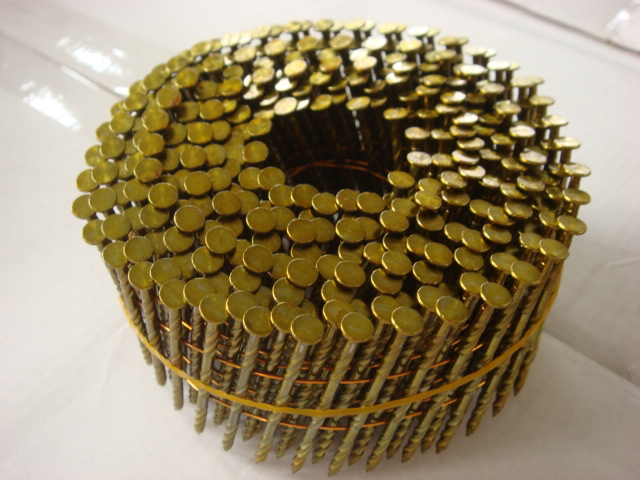

Finished products

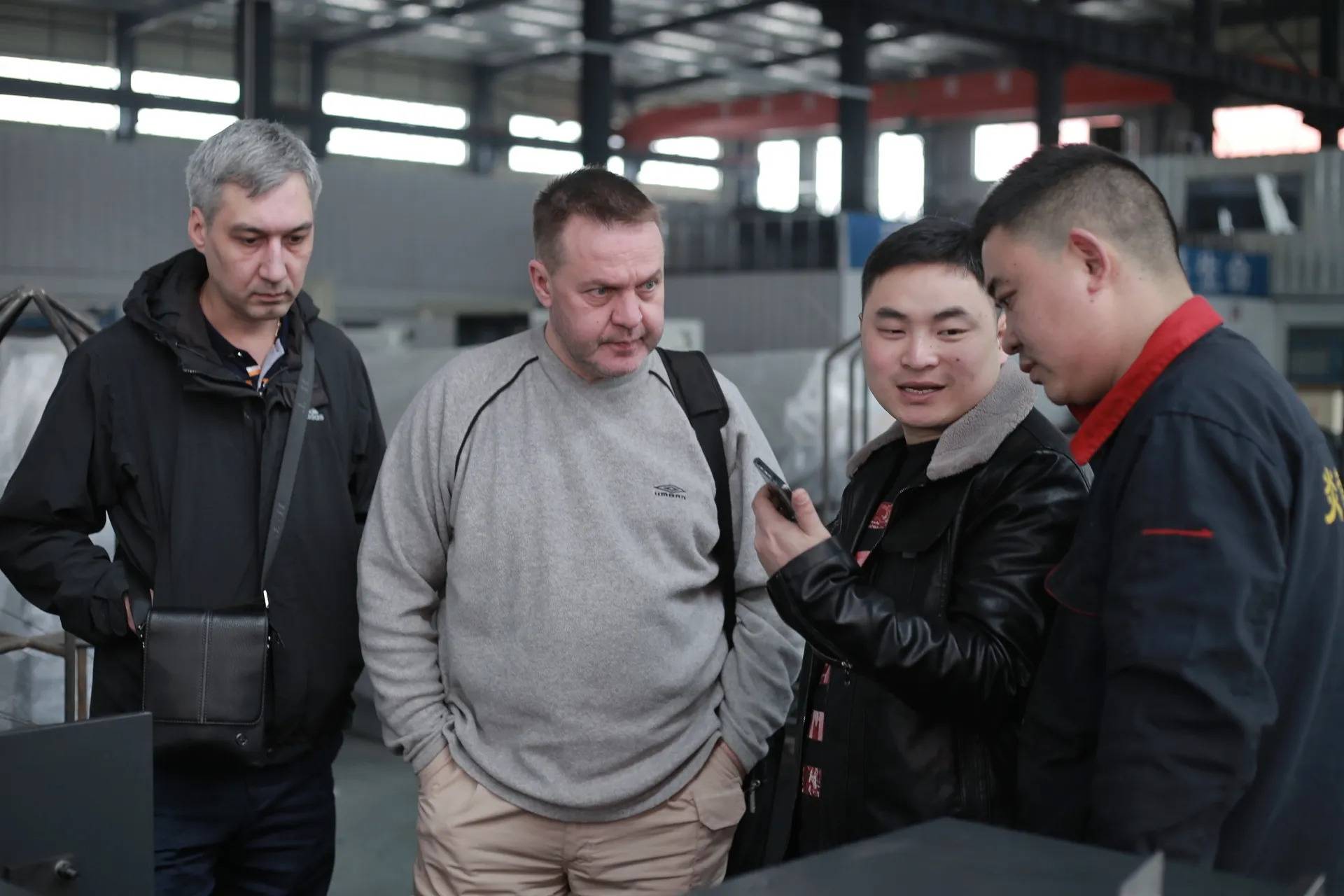

customer visit

Certifications

Packaging and shipping

1. Shipping port: Shanghai

2. Validity: within 30 days

3. Payment terms: 30% T/T down payment in advance and 70% before shipment

4. Warranty: 1 year from date of installation

5. Installation/Operation/Service/Maintenance Manual: Provided In English

6. In wooden pallet, In plastic film, the spare parts and cabinet packed by wooden box.

Our service

1. All required documents (including Installation/Operation/Service/Maintenance Manual) will be provided in English.

2. Engineer will give free training and guide to labors at customer's site if requested.

3. Commissioning charge is $150/day/engineer,and customer will be asked to provide room, meals, round-trip transportation for engineer.

4. We will offer life-long technical guide and maintenance.

5. Warranty:1year from date of installation.

Tags :