This equipment is utilized for producing a variety of staples such as those employed in office as well as those used for industrial purposes. It has replaced the conventional cumbersome technique with a hydraulic system and PLC control, resulting in increased safety during operation, steady output, minimal noise, and improved efficiency. Hence, the nailing machines has been enthusiastically received by most customers.

Overview

Product Description:

This machine has abandoned the traditional heavy-duty punching machine, adopts the hydraulic system as the execution component, and uses the centralized control of the PLC microcomputer.

A. Suitable for 24/6, 26/6, B8, 10 series staple pins.

B. Hydraulic pressure system is adopted in this machine instead of traditional heavy punching type.

C. PLC microcomputer centralized control.

D. Advantages: High speed Safety operation Stable performance Low noise.

|

Main technical datas

|

|||

|

Specifications

|

Unit

|

SSS-TJB-WJ25

24/6

|

SSS-TJB-WJ25

26/6

|

|

Nominal Pressure

|

KN

|

250

|

250

|

|

Number of strokes

|

Times/min

|

100-140

|

100-150

|

|

Wire band width

|

mm

|

100-130

|

100-130

|

|

Wire band thickness

|

mm

|

0.35-0.45

|

0.35-0.45

|

|

Capacity

|

Boxes/min

|

12-18

|

4-7

|

|

Dimensions(L*W*H)

|

mm

|

1345*1170*1700

|

1345*1170*1700

|

|

Motor

|

Kw

|

5.5

|

5.5

|

|

Weight

|

Kg

|

1400

|

1400

|

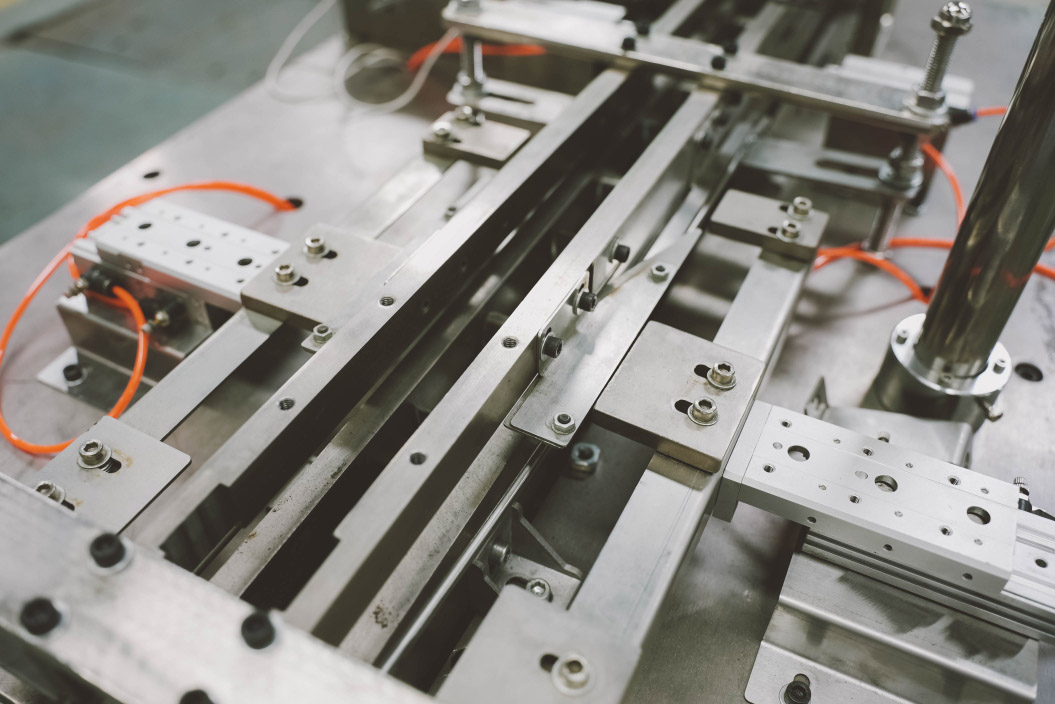

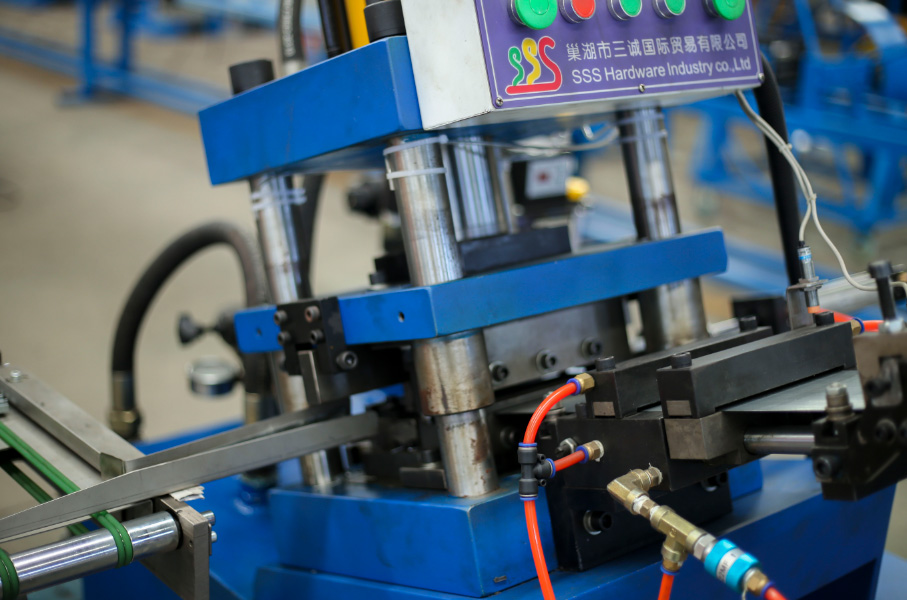

Detail images:

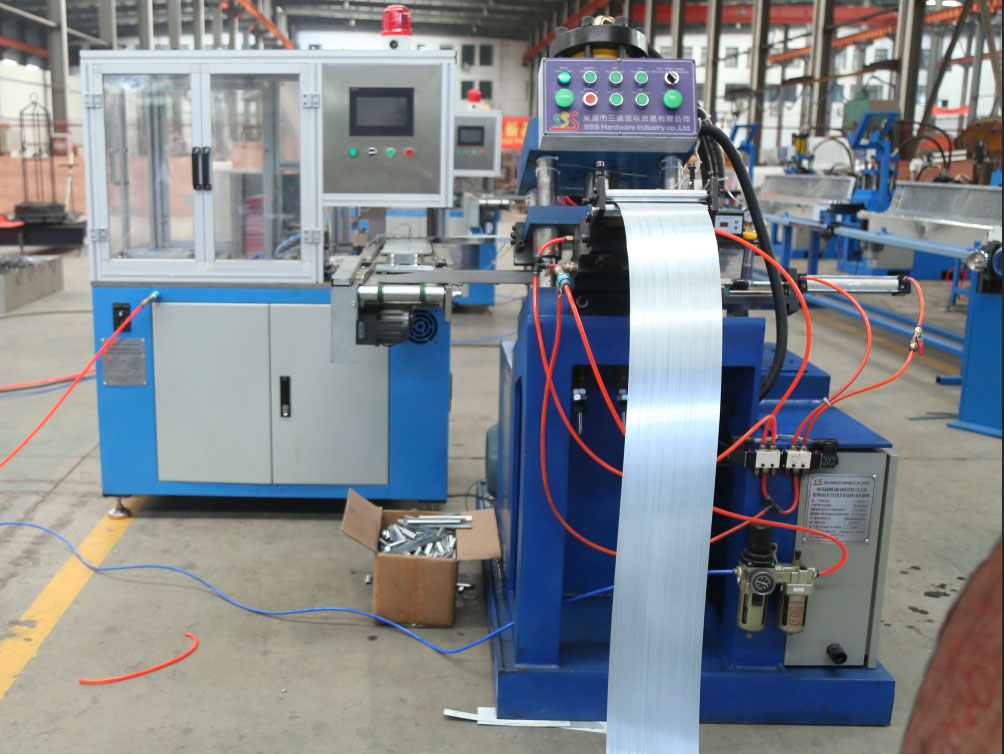

Hydraulic staple making machine

Heavy punching method is abandoned in this machine, and it adopts a hydraulic system for implementation of components, PLC controlled, with characteristics of safety operation, stable performance, low noise and high efficiency. Compared with the traditional punch machine, the speed of this machine is greatly increased.

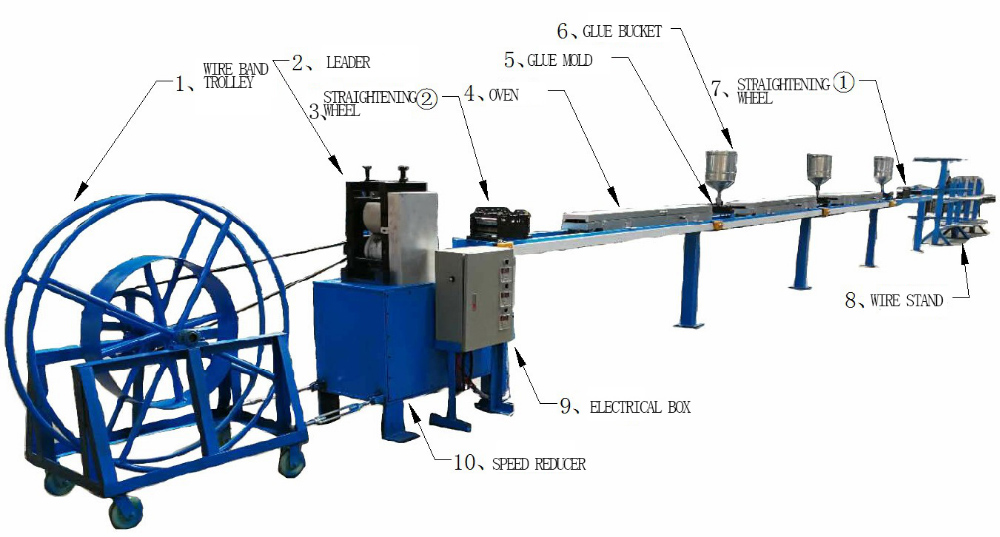

Wire band gluing combiner

This group of machines including wire pay-off frame, front and rear leveling correction equipments which can straighten and glue the wires automatically with automatic drying oven,Wire band gluing combiner which can use glue to combine the single wire to suitable width wire band.

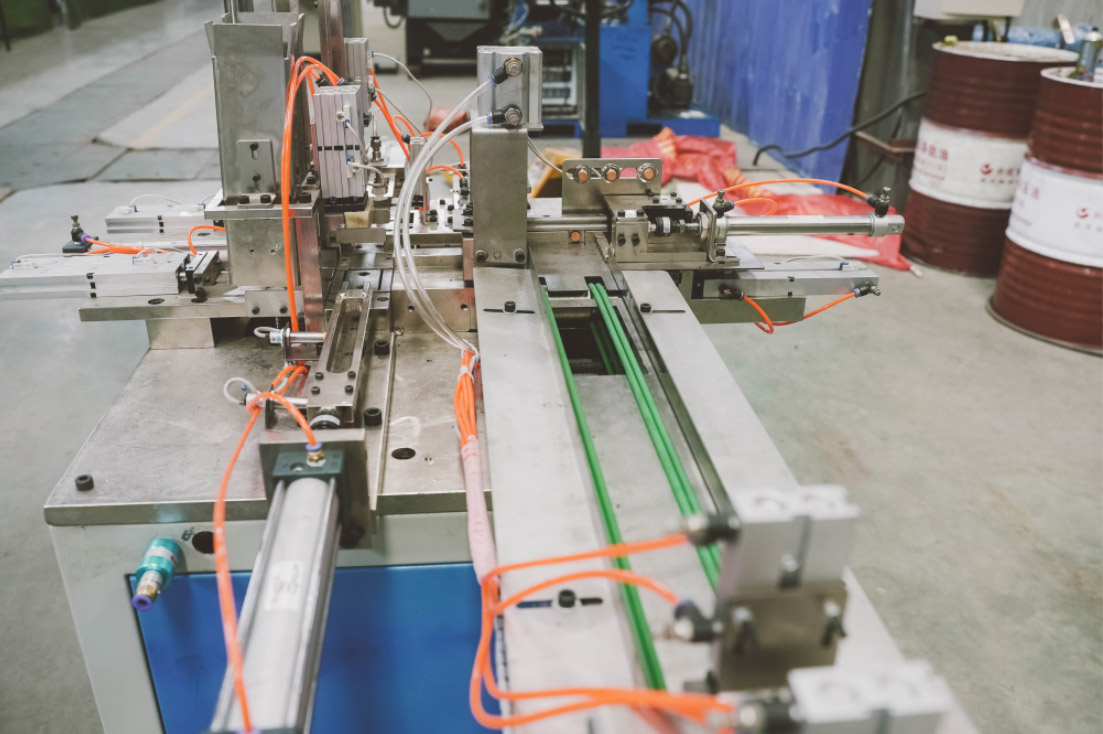

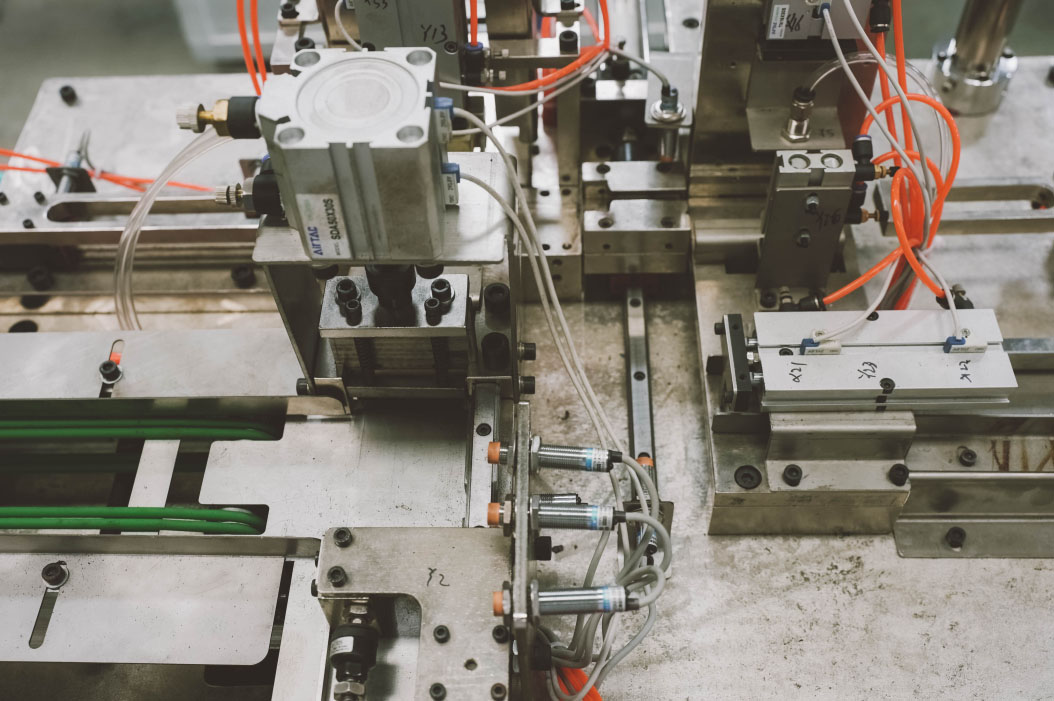

210-spool assy assembly

The 210-spool Assy Assembly with Pulley Cycloidal Devices and Straightening Wheels can get 100% straight wires before flatting. 210 pcs wires can be flattened by Synchronous Flattening wheel at the same time. Two leveling devices before and after gluing Advantages: Each wire gets the same pulling force Even thickness Smooth wire band .

.

Automatic staple packing machine

Power of main motor: 80W Max.

Designed capacity: 40 boxes/min

Machine dimension: 1.2×1.1×1.5m(L×W×H)

Machine weight: about 150Kg

Size of carton: max. 125×45×30mm(L×W×H) min. 120×20×15mm (L×W×H)

Noise:less than 85 db

Main features:

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) Running in a high automatization and intellectualization,no pollution.

Packaging and shipping

1. Shipping port: Shanghai

2. Validity: within 30 days

3. Payment terms: 30% T/T down payment in advance and 70% before shipment

4. Warranty: 1 year from date of installation

5. Installation/Operation/Service/Maintenance Manual: Provided In English

6. In wooden pallet, In plastic film, the spare parts and cabinet packed by wooden box.

Our service

1.All required documents (including Installation/Operation/Service/Maintenance Manual) will be provided in English.

2. Engineer will give free training and guide to labors at customer's site if requested.

3. Commissioning charge is $150/day/engineer,and customer will be asked to provide room, meals, round-trip transportation for engineer.

4. We will offer life-long technical guide and maintenance.

5. Warranty:1year from date of installation.

Tags :